Return to:

Encyclopedia Home Page –

Table of Contents –

Author Index –

Subject Index –

Search –

Dictionary –

ESTIR Home Page –

ECS Home Page

ATOMIC LAYER DEPOSITION BY ELECTROCHEMISTRY

John L. Stickney

Department of Chemistry, University of Georgia

Athens, GA 30602, USA

(June, 2012)

Electrodeposition has served as a thin film preparation method since the 19th century, though it is thought

by some to be more prone to contamination and less

precise than corresponding vacuum processes. With the

introduction of the electrodeposition process for the formation

of interconnects in ultra large scale integration (ULSI), it has

become clear however that electrodeposition can be as clean

as any other thin film deposition technique. This article

argues that electrochemical atomic layer deposition (E-ALD)

can control deposition down to the single atomic layer, and may someday rival molecular beam epitaxy (MBE) for control

in nanofilm growth. This article discusses the

principles on which electrochemical atomic layer deposition is based and the technological opportunities it provides.

Atomic layer deposition (ALD) is a methodology for

forming nanofilms of materials one atomic layer at a time using

surface limited reactions. Surface limited reactions occur only at the substrate

or deposit surface: once the surface (the limiting reagent) is

covered the reaction stops. �Electrochemical atomic layer deposition� (E-ALD or EC-ALD and ECALD) is atomic layer deposition in an electrochemical

environment. Various other names have also been used for electrochemical atomic layer deposition, including �electrochemical atomic layer epitaxy� (EC-ALE or

ECALE). Electrochemical atomic layer deposition is based on underpotential deposition (UPD), which is a type of electrochemical surface limited reaction, where an atomic layer of an element is deposited on the surface, using an electrochemical cell, at an electrode potential lower that needed to deposit the element on itself. This is caused by an energetic effect, where the interaction energy between the element deposited and the surface is larger than the interaction of the element with itself, thus resulting in the formation of a

surface compound or alloy with some energy saving.

The term �atomic layer� refers to a coverage less than a monolayer

(ML), a monolayer being a unit of coverage particular to the deposit

being formed. From a surface chemistry point of view, a monolayer is

formed when there is one deposit atom for each surface atom, at which point the deposition stops. It is possible to produce on the top of this layer another monolayer of a different element, and so on, if the energetics are favorable. A more detailed discussion of this energetics effect and the reactions occurring in the example described below are available in the Appendix.

|

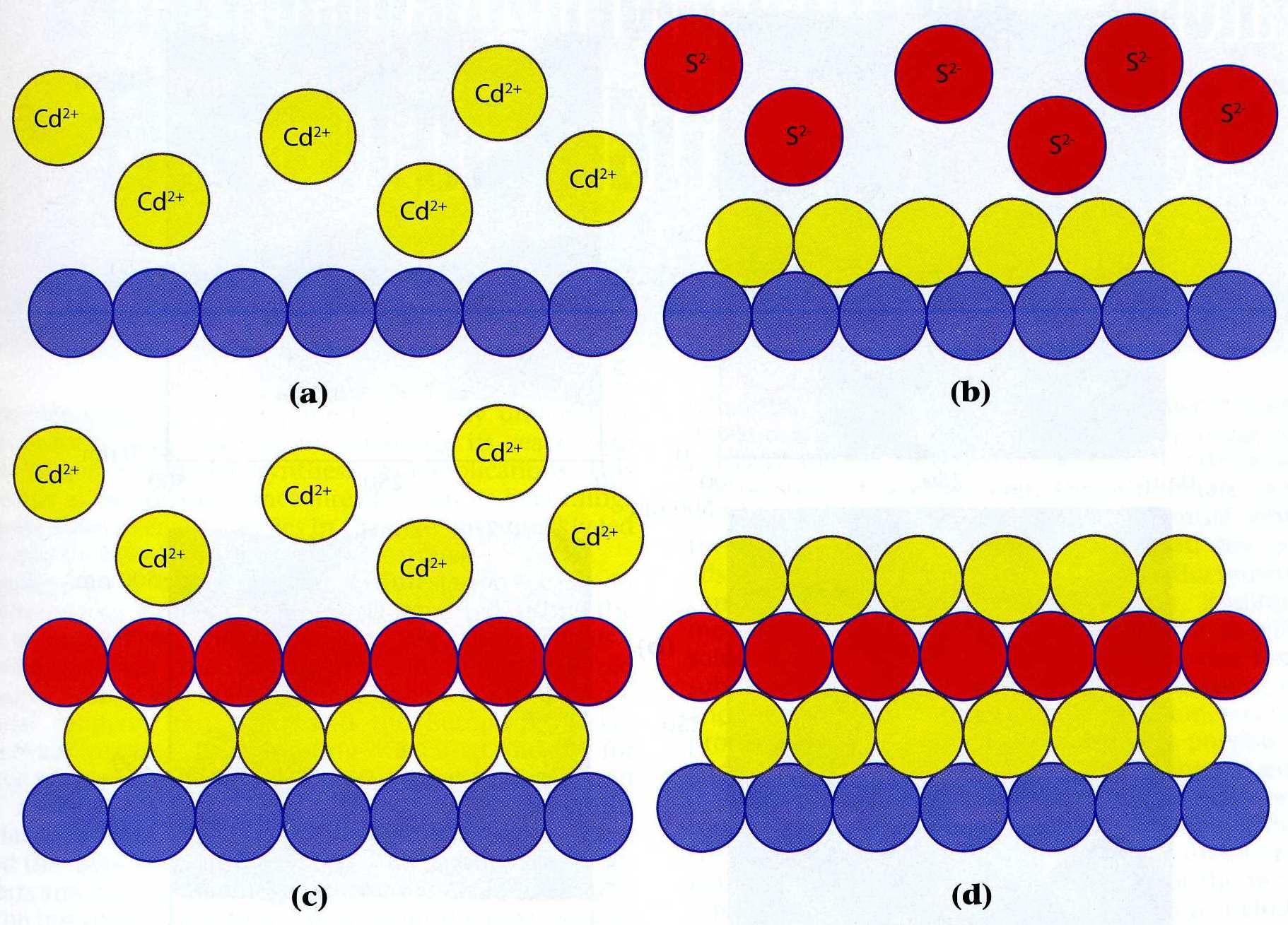

| Fig. 1. Scheme for a cadmium sulfide E-ALD cycle. (a) exchange for cadmium ions, (b) cadmium reductive UPD and exchange for sulfide ions, (c) sulfide oxidative UPD and exchange for cadmium again, (d) one and a half bi-layers of cadmium sulfide. |

Each pair of elements has its own UPD chemistry, which

must be investigated to devise an electrochemical atomic layer deposition cycle. Such a cycle is the sequence of steps used to deposit one stoichiometric layer

of the desired material: this would be an atomic layer for a

pure element, or a bi-layer of a 1:1 compound. The cadmium sulfide electrochemical atomic layer deposition

cycle (Figure 1) is an illustrative example: initially an atomic layer of cadmium is

deposited followed by an atomic layer of sulfur

deposition on the cadmium, and one of cadmium is again deposited on the sulfur.

The cycle is composed of several steps: a reductive underpotential deposition of cadmium

from a cadmium cation solution, a blank rinse, oxidative underpotential deposition of sulfur

from a sulfide anion solution, a blank rinse, a second reductive underpotential deposition of cadmium

from a cadmium cation solution, and one more blank rinse. Separate

solutions are used for each reactant and different potentials for each cycle step. The use of separate solutions and potentials

provides extensive control over deposit growth, composition,

and morphology. A cycle is repeated to form a nanofilm, with

the deposit thickness being a linear function of the number of

cycles. This linear growth is a good indication of a layer by layer

mechanism, and an atomic layer deposition process.

There are a number of cycle chemistries that can be

applied, depending on the depositing elements. The cadmium sulfide

cycle is an oxidative-reductive UPD cycle (O-R). In practice,

few compounds can be formed using O-R, because of a lack of

suitable negative oxidation state precursors (like the sulfide anion), for which

oxidative UPD is practicable. Other cycle chemistries include:

reductive-reductive UPD (R-R), R-R with a reductive strip

(R-R-R), R-R with an oxidative strip (R-R-O), bait and switch

(B&S), and surface limited redox replacement (SLRR).

To achieve compound formation, the applied potentials and

solution compositions for the electrochemical atomic layer deposition cycle should be optimized, resulting in a stoichiometric ratio of atomic layer coverages

each cycle. As long as deposits are formed at underpotentials,

the inherent stability associated with the formation of a

stoichiometric compound will control the atomic layer

coverages. For a binary compound like cadmium sulfide, the atomic layer

coverages will be identical, after the first few cycles. The

amounts of an element deposited during each cycle will be a

function of the potential chosen. The farther the underpotential deposition potential

is from then equilibrium potential (that is, the larger the underpotential), the less of that element that will deposit. In turn, less of the second element will deposit, since its deposition is limited by the availability

of the first element on the surface. Stoichiometric cadmium sulfide will still

result, but the growth will be at a lower rate (nm/cycle).

The above discussion suggests that each cycle results in a

conformal compound layer, deposited over the whole surface.

The rules for thin film formation still apply, however. Lattice

matching with the substrate, for instance, is still an issue, and

strain will increase as the number of cycles increases. Strain

will be released when the critical thickness is achieved, with

the formation of threading dislocations and other defects.

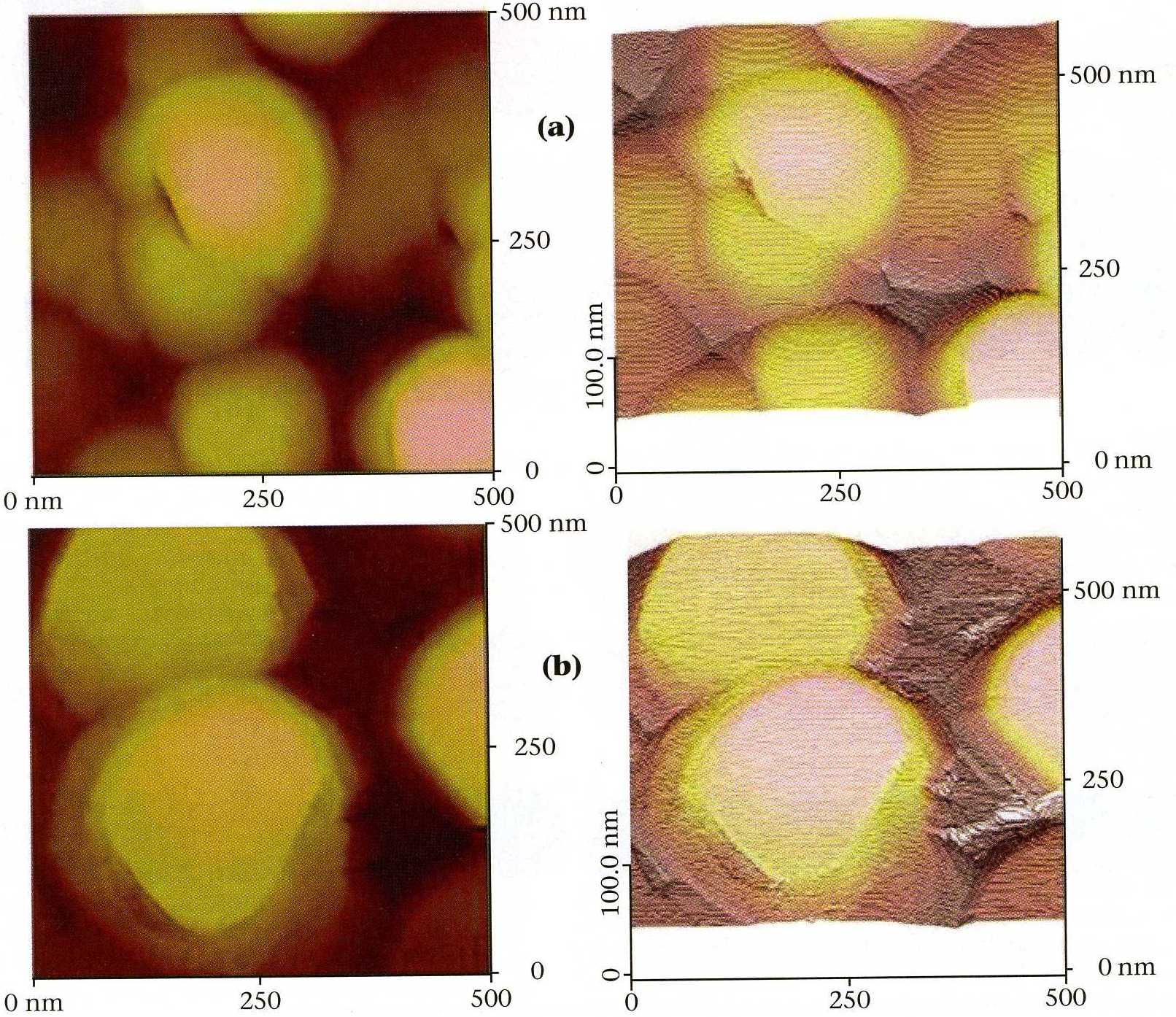

The substrate may be a single crystal, wafer, polycrystalline

film, foil, or powder. Each crystallographic facet will have a

different affinity for the depositing element, and will result in a

different coverage and interface structure. When various facets

coalesce, grain boundaries will form, and the cycle conditions

chosen will determine the resulting deposit morphology. Use

of more aggressive conditions (smaller underpotentials) could

cause roughening at grain boundaries, while use of larger

underpotentials could minimize deposition at the boundaries

(Figure 2). Even when a single crystal is used as a substrate, there

will be steps and defects, which may nucleate different deposit

structures and orientations. The first electrochemical atomic layer deposition cycle is performed on the substrate, generally a different material. The optimal

deposition conditions for the first few cycles may thus differ

from the steady state conditions used to grow the remaining

nanofilm, where the compound deposits on itself.

|

| Fig. 2. Scanning tunneling microscopy images: (a) gold vapor deposited on glass; (b) 30 superlattice periods, each consisting of 3 cycles of lead selenide, followed by 15 cycles of lead telluride, on the gold

vapor deposited on glass. Note the nearly atomically flat terraces resulting from the E-ALD deposit. |

One of the major differences between electrochemical atomic layer deposition and the

various vacuum and gas based deposition methodologies,

besides use of a condensed phase, is temperature. Electrochemical atomic layer deposition is performed at room temperature or under the boiling point of

the solvent, all of which are considered �low temperature� for

thin film formation. Despite formation at �low temperature,�

the deposits form under equilibrium conditions. The

deposition potential is applied until the current goes to zero and the composition and structure are constant, indicating

that equilibrium has been reached for that potential. This is made possible by the exchange current. Electrochemical deposition is a dynamic process, where atoms are depositing and dissolving at the same time. The measured current is

the difference between the deposition and dissolution flux,

and when it is zero, equilibrium has been established. The exchange current

is a measure of the rate at which atoms are depositing and dissolving, at equilibrium. Ideally, atoms in high energy sites are dissolving and redepositing in more stable sites. The result

is similar to thermal annealing, or to surface diffusion, in gas

or vacuum phase thin film deposition methods. Several other

electrodeposition methodologies benefit from depositionat potentials near equilibrium; however, many involve

overpotential deposition, where the contribution of exchange current is insignificant, so that deposited atoms tend not to redissolve,

and deposits become disordered.

An increasing number of groups around the world have

been using electrochemical atomic layer deposition to form a wide variety of materials for a wide variety of applications. Different nanofilms are formed

for infrared detector materials, thermoelectric materials, and photovoltaic materials.

Most electrochemical atomic layer deposits are formed using some type of

electrochemical flow cell that allows for the rapid exchange of solutions, in combination with automation, the cycle can be programmed, and

allowed to run for as many cycles as desired. Graduate students

manually performing cycles usually tire and make mistakes

somewhere after the 10th cycle. The more elements involved

in the deposit, the more solution lines are required. More

complex sequences of potentials and solution exchanges can be performed as well, such as the formation of a superlattice

where two or more materials are alternated to form materials

with unique lattice constants, and optical and electronic properties (Figure 2).

Appendix

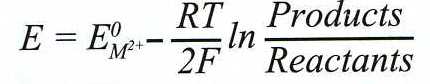

In electrodeposition, the metal ion reduction to the element,

[1]  M2+ + 2 e- ==> M M2+ + 2 e- ==> M

is generally controlled by the applied potential, which is dictated by

the activity ratio of products to reactants according to the

Nernst equation:

[2]

Conventionally, the product is a bulk metal with an activity of

unity. In underpotential deposition, however, the product is an atomic layer, which

has a different electronic structure than the bulk metal, due to its interaction with the substrate. The activity of the product

is then less than unity, shifting the equilibrium potential, and accounting for underpotential deposition, which occurs when the depositing element is more stable on the substrate than on itself. Underpotential deposition is fundamentally an surface limited reaction, as long as the applied potential is under the potential for bulk deposition, in the given

solution. Bulk deposits do not form at an underpotential,

regardless of the deposition time.

The reactions occurring in the example shown in Figure 1 are:

[3]  Cd2+ + 2 e- ==> CdUPD Cd2+ + 2 e- ==> CdUPD

[4]  S2- ==> SUPD + 2 e- S2- ==> SUPD + 2 e-

Acknowledgements

This article was reproduced from The Electrochemical Society Interface (Vol. 20, No. 2, pp 28-30, Summer 2011) with permission of The Electrochemical Society, Inc. and the author.

Related article

Electroplating

Bibliography

- Electrodeposition of Compound Semiconductors by Electrochemical Atomic Layer Epitaxy (EC-ALE), J. L. Stickney, T. L. Wade, B. H. Flowers, R. Vaidyanathan, and U. Happek, in �Thermodynamics and Electrified Interfaces� (Encyclopedia of Electrochemistry, Vol. 1) pp 513-560, E. Gileadi and M. Urbakh (editors), Wiley-VCH, Weinheim, Germany, 2002.

- Electrochemical Atomic Layer Epitaxy (EC-ALE): Nanoscale Control in the Electrodeposition of Compound Semiconductors, J. L. Stickney, in �Advances in Electrochemical Science and Engineering� Vol. 7, pp 1-105, R. C. Alkire and D. M. Kolb (editors), Wiley-VCH, Weinheim, Germany, 2002.

- Electrochemical Atomic Layer Epitaxy, J. L. Stickney, in �Electroanalytical Chemistry: a Series of Advances� Vol. 21, pp 75-210, A. J. Bard and I. Rubinstein (editors), Marcel Dekker, New York, 1999.

- Epitaxial Compound Electrodeposition, T. L. Wade, T. A. Sorensen, and J. L. Stickney, in �Interfacial Electrochemistry: Theory, Experiment and Applications� pp 757-768, A. Wieckowski (editor), Marcel Dekker, New York, 1999.

Listings of electrochemistry books, review chapters, proceedings volumes, and full text of some historical publications are also available in the Electrochemistry Science and Technology Information Resource (ESTIR). (http://knowledge.electrochem.org/estir/)

Return to:

Top –

Encyclopedia Home Page –

Table of Contents –

Author Index –

Subject Index –

Search –

Dictionary –

ESTIR Home Page –

ECS Home Page

|